Cleaning systems

Cleaning equipment and systems

Customized cleaning systems

JNW CleaningSolutions delivers cleaning equipment from simple manual cleaning chassis to fully-automatic cleaning system, which are integrated in the central control room of the plant.

Our range of services comprises:

- Basic and detail engineering

- Production in our own workshop in Germany

- Function test of the cleaning system in our workshop

- Delivery worldwide

- Installation and commissioning all over the world

- Training of the operating staff on site

- Spare parts supply and maintenance on site.

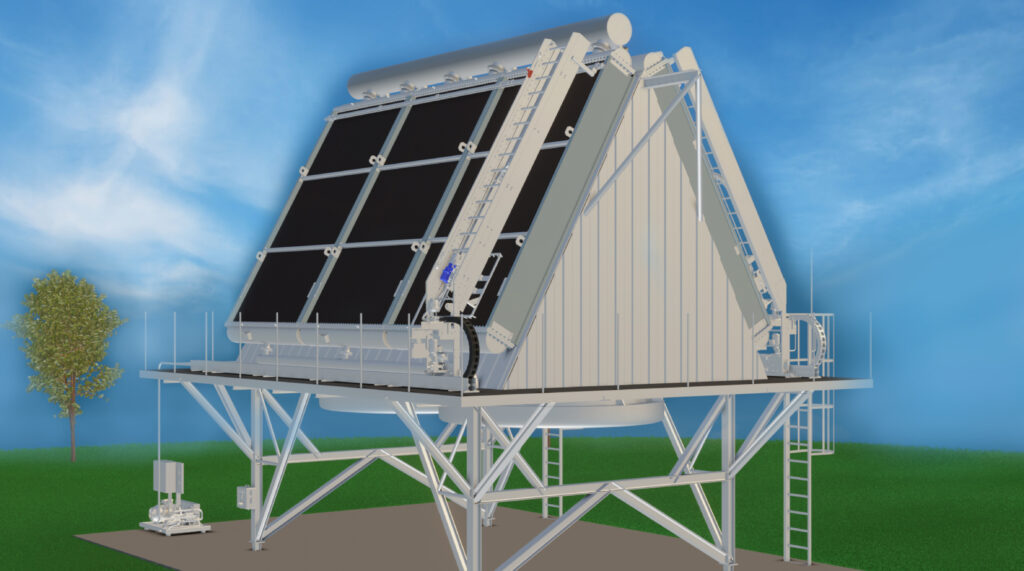

In addition to the cleaning equipment and systems standardized to large extent for air-cooled condensers (ACC) and induced or forced draft flat-bed coolers, we offer also special designs and solutions for most various heat exchanger types and versions.

Fully-automatic cleaning system – the JNW Cleaning Robot

When JNW talk about fully automatic cleaning systems we mean it. Because our JNW Cleaning Robot cleans your heat exchanger on its own. After pressing the start button and the PLC of the JNW Cleaning Robot takes over the complete control of the cleaning process from the first to the last water jet.

Operating staff on site at the cleaning system is no longer required for start, control and ending of the cleaning process. After the cleaning has been completed the JNW Cleaning Robot furthermore parks the cleaning chassis in its parking position, it closes the water valves that it opened before and switches the entire system off.

The control of the JNW Cleaning Robot is either done by a master control panel (MCP) positioned at the cooler or from the central control room by integrating the system using an interface. The JNW Cleaning Robot is likewise guided in rails and delivered with all necessary equipment items such as rail system, high-pressure pump, high-pressure hoses, cables and controller (including PLC).

The cleaning chassis of the cleaning system can be made accessible or not accessible.

Semi-automatic cleaning system

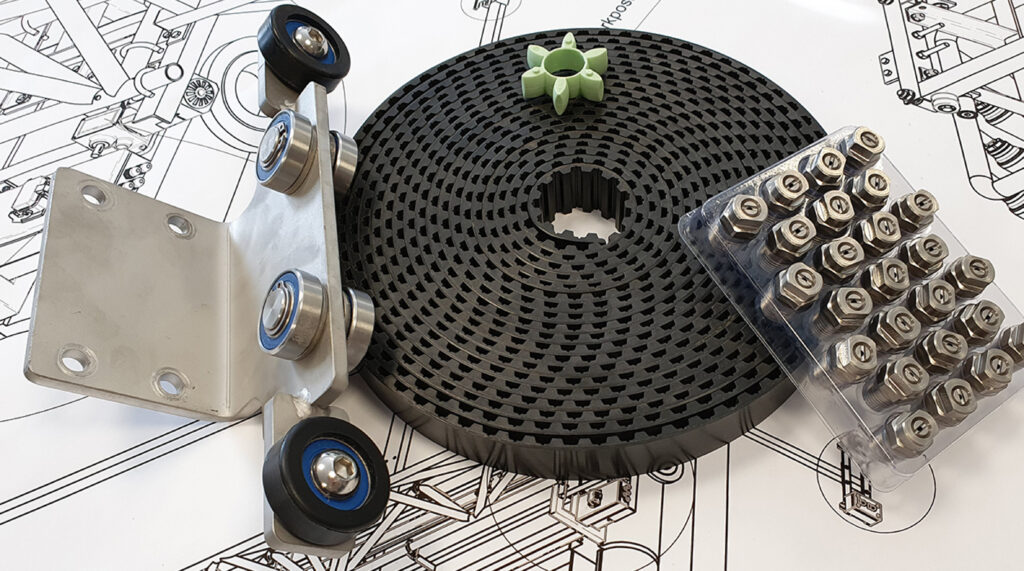

Semi-automated cleaning chassis are equipped with a nozzle beam each electrically driven in vertical direction by a tooth belt. The control of the nozzle beam is executed by the operator with a mobile control panel.

The cleaning chassis, however, is manually moved in horizontal direction by the operator. For that purpose, the cleaning chassis is guided in rails and individually adapted to the constructive conditions of the heat exchanger.

The cleaning chassis is made of aluminium and can be delivered as walkable and non-walkable execution. The other components of the cleaning system are made of stainless steel and/or in temperature and corrosion resistant materials.

The system is delivered as complete cleaning system including control panel, high-pressure pumps, high-pressure hoses, cables, rails and holders.

JNW- Cleaning chassis

This manual system is a simple walkable cleaning chassis made of aluminium without any further cleaning equipment. It enables an access to the cooler surface for maintenance or manual cleaning of the cooler.

The cleaning chassis is horizontally moved by hand as well as additionally guided in the head area on rails and individually adapted to the constructive conditions of the heat exchanger.

The cleaning chassis has been prepared for the installation of nozzle beam, electric drive, tooth belts, etc. so that at any time retrofitting and upgrading of the cleaning chassis to a semi-automatic cleaning system is possible.